Product Series

-

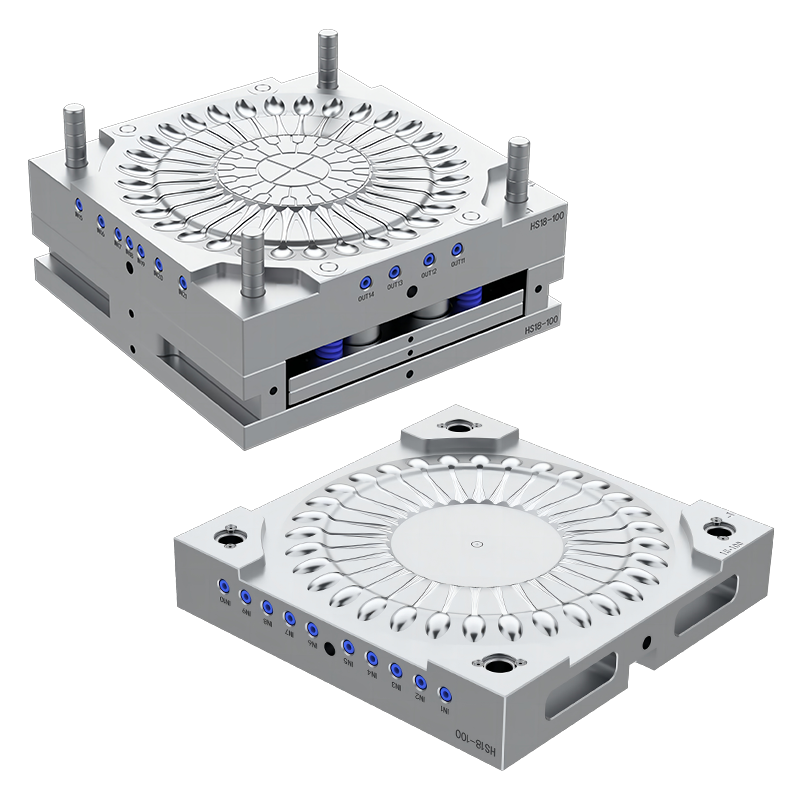

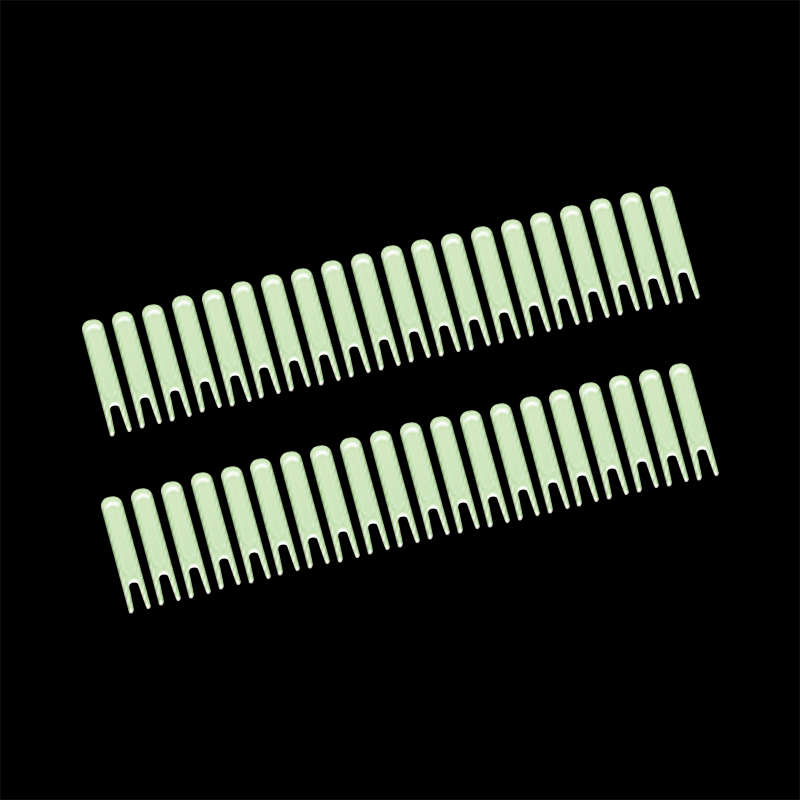

- Disposable Plastic Round Food Container Moulds

-

- Disposable Plastic Square Food Container Moulds

-

- Disposable Bubble Tea Plastic PP Cup Mould Series

-

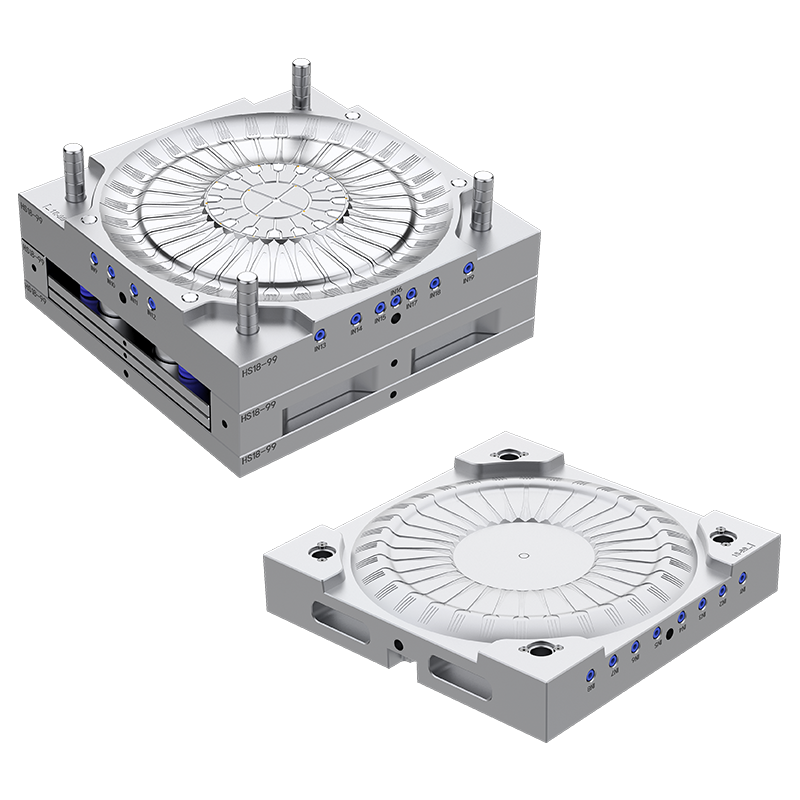

- Disposable Plastic Knife Fork And Spoon Mould Series

-

- Disposable Plastic Multi-grid Food Container Mould Series

-

- Disposable Plastic Portion Cup Mould Series

-

- Disposable Plastic Cup Mould Series

Plastic Fork Mold Company

The Disposable Plastic Knife Fork And Spoon Mould Series represents a comprehensive range of high-precision molds designed for the efficient production of disposable plastic cutlery. These molds are ideal for producing large quantities of knives, forks, and spoons in a single cycle, with a molding cycle of less than 6 seconds or within 6-8 seconds. The series includes thin-walled plastic injection molds and offers options with a high number of mold cavities, such as 32 and 48, ensuring high-volume production capabilities.

Product Advantages

Efficiency in Production

1. Short Molding Cycle

- The Disposable Plastic Knife Fork And Spoon Mould Series has a molding cycle of 6 to 8 seconds, significantly reducing production time.

- This short cycle time allows for rapid turnaround, increasing overall productivity and output.

2. High-Capacity Molds

- With mold cavities ranging from 32 to 48, the series can produce a large number of cutlery pieces in each cycle.

- This high capacity makes it possible to meet large-scale production demands efficiently.

High Precision

1. Consistency and Quality

- The high precision of the Disposable Plastic Knife Fork And Spoon Mould Series ensures that each piece of cutlery produced is of uniform quality.

- Consistent production helps maintain the reliability and reputation of the final products.

2. Thin-Walled Injection Molding

- These molds are designed for thin-walled plastic injection molding, which results in lightweight yet durable cutlery.

- Thin-walled molding reduces material usage without compromising the strength and usability of the cutlery.

Cost-Effectiveness

1. Material Efficiency

- The design of the Disposable Plastic Knife Fork And Spoon Mould Series minimizes material waste, making the production process more cost-effective.

- Efficient material usage contributes to lower production costs and increased profitability.

2. Reduced Labor Costs

- The automation and efficiency of these molds reduce the need for manual intervention, lowering labor costs.

- Fewer manual processes lead to faster production times and lower operational expenses.

Product Features

High-Precision Engineering

1. Accurate Mold Design

- The Disposable Plastic Knife Fork And Spoon Mould Series is engineered with precision to ensure accurate and consistent cutlery shapes.

- Detailed mold design ensures each piece meets the required specifications and quality standards.

2. Durable Construction

- Made from high-quality materials, these molds are built to withstand the rigors of high-volume production.

- Durable construction ensures long-lasting performance and reliability.

Versatile Applications

1. Multiple Cavity Options

- The series includes molds with various cavity options, such as 32 and 48 cavities, to cater to different production needs.

- This versatility allows manufacturers to scale production according to demand.

2. Compatibility with Different Materials

- The Disposable Plastic Knife Fork And Spoon Mould Series is compatible with various plastic materials, offering flexibility in production.

- This compatibility ensures that manufacturers can choose the best material for their specific application.

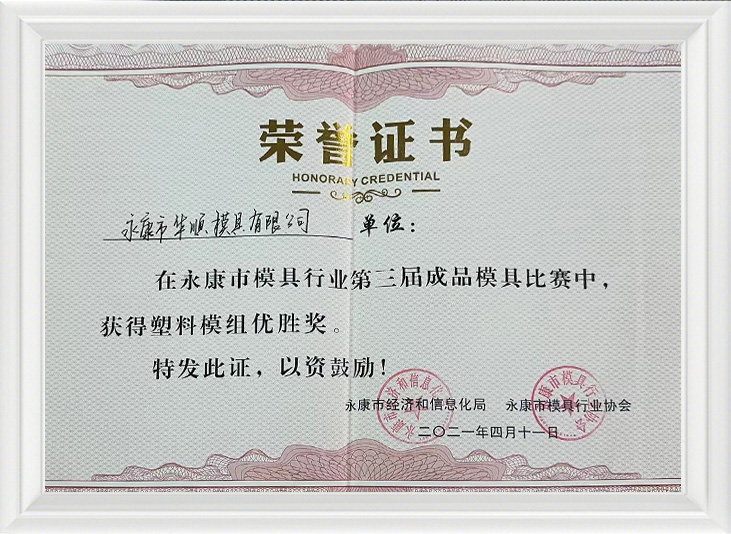

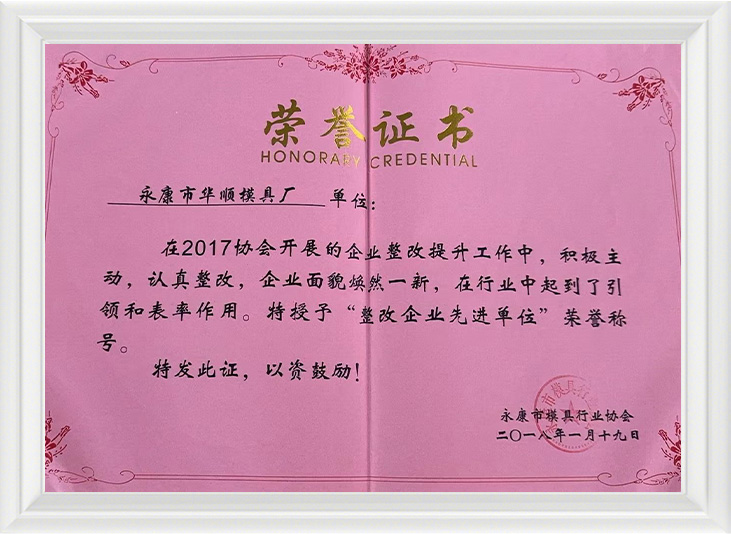

Why Choose Us

1. Quality Assurance

- We implement rigorous quality control measures to ensure each mold meets high standards of precision and durability.

2. Comprehensive Support

- Our team provides comprehensive technical support to help you with the installation and operation of the Disposable Plastic Knife Fork And Spoon Mould Series.

3. Innovation and Development

- We are committed to continuous improvement, regularly updating our molds to incorporate the latest advancements in injection molding technology.

WHO ARE WE

LATEST NEWS

-

What is a mould for plastic cups?

What is a Mould for Plastic Cups? A mould for plastic cups is a tool used in the plastic manufacturing industry to shape thermopla...

Read More >>> 2026-01-23 -

The Lunch Box Mold: A Multifaceted Manufacturing Tool

The lunch box mold is a precision tool used in injection molding to manufacture the plastic containers commonly used for storing a...

Read More >>> 2026-01-16 -

What are the main functions of Food Container Mold?

The Food Container Mold performs several critical and interdependent functions during the injection molding process. Forming the ...

Read More >>> 2026-01-09 -

How to Choose a Spoon Mold?

Spoon molds are important tools in the manufacturing of plastic, metal, or wooden spoons. They determine the shape, size, and cons...

Read More >>> 2026-01-02

Contact Us

Email: [email protected]; Or fill out the contact form below.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français