Types of Plastic Food Container Mold

Plastic food containers have become essential in modern households, restaurants, and food processing industries. Their convenience, durability, and ability to maintain food freshness make them a popular choice. The molds used to produce these containers are a critical factor in determining quality, consistency, and production efficiency.

Types of Plastic Food Container Molds

1. Two-Plate Mold

Two-plate molds are the commonly used type for plastic food containers. They consist of a cavity plate and a core plate that form the shape of the container.

Key Features:

Simple and easy to maintain.

Produces a single container per injection cycle.

Suitable for standard designs and moderate production volumes.

Two-plate molds are ideal for small to medium-scale manufacturers and for producing basic container shapes such as rectangular, square, or circular boxes.

2. Three-Plate Mold

Three-plate molds include an additional runner plate between the cavity and core plates, allowing for more complex designs and better material flow.

Key Features:

Capable of producing containers with intricate details or multiple cavities.

Ensures uniform wall thickness and consistent shape.

Suitable for high-volume production with minimal defects.

Three-plate molds are commonly used in commercial food container manufacturing where precision and efficiency are essential.

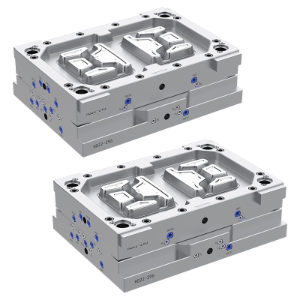

3. Stack Mold

Stack molds are designed to produce multiple containers in a single molding cycle by stacking cavities vertically.

Key Features:

Increases production output without requiring additional machines.

Reduces overall cycle time for large-scale manufacturing.

Requires careful alignment for consistent quality.

Stack molds are ideal for large-scale production lines in the food packaging industry, where high output is necessary to meet demand.

4. Hot Runner Mold

Hot runner molds use heated channels to keep the plastic molten as it flows into the cavities, reducing waste and improving efficiency.

Key Features:

Minimizes scrap material and reduces cycle time.

Produces containers with smooth surfaces and consistent wall thickness.

Ideal for high-precision and high-volume production.

Hot runner molds are suitable for manufacturers looking to reduce material waste while producing high-quality food containers.

5. Cold Runner Mold

Cold runner molds use standard channels to guide molten plastic into the cavity. After each cycle, the runner solidifies and is either recycled or discarded.

Key Features:

Lower initial investment compared to hot runner molds.

Easier to modify for different container designs.

Suitable for small to medium production volumes.

Cold runner molds are practical for businesses producing standard containers or experimenting with new shapes and sizes.

6. Custom Mold

Custom molds are designed to meet specific client requirements, allowing unique shapes, sizes, or features.

Key Features:

Enables creation of specialized containers, such as those with compartments or snap-lock lids.

Suitable for niche markets or promotional products.

Offers flexibility in design while maintaining production quality.

Custom molds are preferred by manufacturers targeting specialized food packaging solutions or brand-specific designs.

Uses of Plastic Food Container Molds

1. Household Food Storage

Plastic containers produced from these molds are commonly used for storing leftovers, meal prep, or organizing pantry items. Their lightweight and durable design make them convenient for everyday use.

2. Takeaway and Food Delivery

Restaurants and catering services use molded plastic containers for takeaway and delivery. High-quality molds ensure containers are leak-proof, stackable, and durable enough to transport food safely.

3. Refrigeration and Freezing

Molds designed for freezer-safe containers produce items that can withstand low temperatures without cracking. These containers are widely used for storing prepared meals, vegetables, or soups.

4. Food Processing Industry

Plastic containers molded for industrial applications are used for packaging, portioning, and distributing food products. Stackable designs and standardized sizes enhance storage efficiency and transportation.

5. Specialty Containers

Custom molds allow for containers with compartments, snap-on lids, or unique branding. These are used in school lunchboxes, meal kits, or promotional packaging for commercial products.

Considerations When Choosing Plastic Food Container Molds

Production Volume: Multi-cavity or stack molds are ideal for high-volume production, while single or two-plate molds suit smaller batches.

Material Type: Consider the type of plastic, such as polypropylene (PP) or polyethylene (PE), for durability, heat resistance, and food safety.

Design Complexity: Choose molds that match the desired container shape, size, and features.

Precision Requirements: Hot runner or precision molds ensure consistent wall thickness and smooth surfaces.

Maintenance: Durable molds with easy maintenance ensure long-term, reliable production.

Contact Us

Email: [email protected]; Or fill out the contact form below.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français