The Technological Revolution of Thin Wall Injection Moulding

Thin Wall Injection Moulding refers to the injection moulding process used to produce plastic components with thin, uniform walls. The thickness of these walls typically ranges from 0.5 mm to 3 mm, depending on the application. This process involves injecting molten plastic into a mould cavity under high pressure, where it cools and solidifies into the desired shape. It is particularly advantageous for producing high volumes of lightweight parts with precision and strength.

With applications across a wide variety of industries, Thin Wall Injection Moulding is a critical technique for manufacturing products such as food containers, cosmetic packaging, medical devices, and automotive parts. As industries continue to evolve, so does the technology behind this moulding technique, enabling manufacturers to meet the increasing demands for efficiency, quality, and sustainability.

Advances in Mould Design and Material Selection

One of the primary areas where Thin Wall Injection Moulding has seen technological improvements is in mould design and material selection. Traditionally, thin-walled components were challenging to produce because achieving uniform wall thickness and strength was difficult. However, innovations in mould design have made it easier to produce these components efficiently.

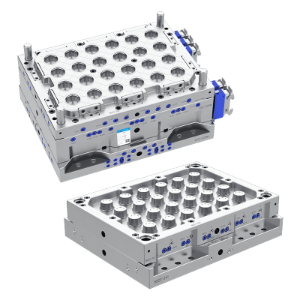

Modern Thin Wall Injection Moulding uses advanced mould designs that incorporate optimized cooling channels, which ensure even cooling throughout the mould cavity. This helps prevent defects such as warping or uneven wall thickness. The use of hot runner systems has also significantly improved the process by allowing for more consistent material flow, reducing waste, and enhancing overall efficiency.

In addition, advancements in material science have played a key role in the revolution of Thin Wall Injection Moulding. The development of new thermoplastic materials, such as polypropylene (PP), polyethylene (PE), and other advanced resins, has enabled manufacturers to produce thin-walled components with improved strength, durability, and flexibility. These materials offer better resistance to heat, chemicals, and wear, making them ideal for use in industries like packaging and automotive.

Improved Injection Moulding Machinery

The machinery used in Thin Wall Injection Moulding has also undergone significant technological improvements. Older injection moulding machines struggled to provide the necessary pressure and temperature control required for producing thin-walled parts with high precision. However, the latest machines are equipped with more advanced features, such as enhanced clamping force, higher injection pressures, and precise temperature regulation.

These improvements have made it possible to manufacture thinner walls with greater consistency, reducing the likelihood of defects and increasing the overall quality of the finished product. Furthermore, modern injection moulding machines are often equipped with automated systems for monitoring the process, ensuring that every part meets the desired specifications. These systems can track variables like injection speed, temperature, and pressure in real time, allowing manufacturers to quickly identify and address any potential issues.

Faster Production Times and Higher Efficiency

One of the primary driving forces behind the revolution of Thin Wall Injection Moulding has been the ability to increase production speeds while maintaining high quality. Faster cycle times are crucial for meeting the growing demand for thin-walled plastic products in industries like food packaging and consumer goods. Through advancements in technology, manufacturers can now produce thinner, stronger parts at a much faster rate than ever before.

For example, the integration of more efficient cooling systems has allowed for quicker solidification of the plastic, which in turn shortens cycle times. The use of multi-cavity moulds—moulds that can produce multiple parts simultaneously—has further accelerated production. By producing several parts at once, manufacturers can achieve higher output levels, making Thin Wall Injection Moulding even more cost-effective for high-volume production.

Additionally, improvements in automation have helped streamline the entire process. Robots and automated systems are now commonly used to remove finished parts from the mould, inspect them for defects, and prepare them for packaging or further assembly. These automated systems not only increase production speeds but also reduce labor costs and improve overall efficiency.

Contact Us

Email: [email protected]; Or fill out the contact form below.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français