How to Choose the Right Plastic Food Container Mould: Key Considerations

When it comes to producing plastic food containers, selecting the appropriate mould is essential for achieving the desired quality, efficiency, and cost-effectiveness. A well-designed plastic food container mould not only ensures that the final product meets industry standards but also plays a significant role in streamlining production processes.

Material Compatibility

The consideration when selecting a plastic food container mould is the compatibility with the material to be used. Different plastics offer unique characteristics that influence the functionality, durability, and overall performance of the container. The common plastics used for food containers include polypropylene (PP), polyethylene (PE), polyethylene terephthalate (PET), and polystyrene (PS). Each of these materials has distinct properties that should align with the mould design.

Polypropylene (PP): PP is known for its flexibility, heat resistance, and chemical stability, making it a popular choice for food containers that require microwave and dishwasher-safe features. The mould should be designed to accommodate the unique properties of PP, ensuring smooth material flow during injection and precise shaping of the container.

Polyethylene (PE): PE is widely used for its durability and impact resistance. When choosing a mould for PE, it is important to ensure that it can handle the material's higher viscosity, ensuring uniform wall thickness and consistent quality.

Polyethylene Terephthalate (PET): PET is commonly used for clear, lightweight containers such as beverage bottles. Moulds designed for PET containers need to accommodate the material's specific characteristics, such as its tendency to shrink slightly during cooling.

Polystyrene (PS): PS is often used for containers requiring a rigid structure. Moulds for PS must allow for quick and uniform cooling to prevent warping or deformation.

Choosing the right plastic food container mould requires understanding the properties of the material being used and selecting a mould that optimizes the material's advantages while reduce its limitations.

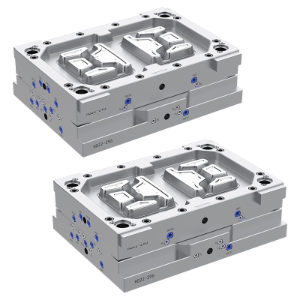

Mould Design and Shape

The design of the plastic food container mould is another critical factor in the selection process. The complexity of the mould design directly influences the functionality and efficiency of the container, as well as the production process.

Simple vs. Complex Designs: Moulds for basic food containers, such as rectangular or round shapes, are relatively straightforward. However, for custom-shaped containers, such as those with compartments or specialized lids, a more complex mould design is required. The more intricate the design, the more advanced the mould needs to be to ensure precise and consistent results.

Lid Design: Many food containers require a lid, and the mould design should incorporate a mechanism for forming an airtight or leak-proof seal. It is essential to choose a mould that can create containers with features such as snap-on lids, screw tops, or hinged designs, depending on the type of food container.

Stackability and Nesting: For convenience and efficiency in storage and transport, food containers are often designed to stack or nest. Moulds for these containers need to be designed to ensure the containers can be stacked securely without compromising the integrity of the container's shape.

Ventilation and Drainage Features: Certain food containers, such as those used for fresh produce or seafood, require ventilation or drainage to ensure the product stays fresh. Moulds for these containers should incorporate features such as perforations, vents, or raised structures to allow airflow and prevent moisture buildup.

Contact Us

Email: [email protected]; Or fill out the contact form below.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français