The Lunch Box Mold: A Multifaceted Manufacturing Tool

The lunch box mold is a precision tool used in injection molding to manufacture the plastic containers commonly used for storing and transporting meals. Its role extends beyond simply shaping plastic; it is an integrated system that dictates the final product's form, function, and feasibility for mass production. To fully understand its significance, the lunch box mold can be examined from four distinct yet interconnected perspectives: its functional design engineering, its economic rationale, its role in material science application, and its considerations for end-user interaction. Each perspective reveals a different facet of how this tool bridges the gap between industrial capability and a ubiquitous consumer product.

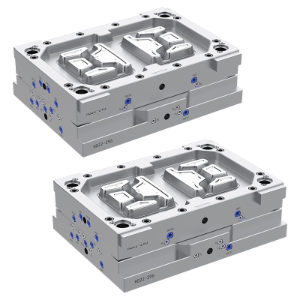

Perspective One: Functional Design and Engineering

From an engineering standpoint, the lunch box mold is a complex assembly of hardened steel components designed to perform under high pressure and temperature. Its primary function is to form the plastic into a specific, repeatable geometry. This involves the cavity and core inserts, which create the hollow shape of the box and its lid. The mold must incorporate features for undercuts, such as the latch mechanism or the hinge for a flip-top box, which require movable slides or lifters in the mold that retract before the part can be ejected. Furthermore, the engineering perspective prioritizes the cooling system—a network of channels through which water circulates to solidify the plastic efficiently. The design of this system directly determines the production cycle time, making it a critical factor for manufacturing speed and cost. Engineering also addresses ejection, ensuring the finished part is cleanly pushed from the mold without distortion using a system of ejector pins or plates.

Perspective Two: Economic and Production Rationale

Economically, the mold represents a significant capital investment that enables high-volume, low-cost production. Its existence is justified by the principles of economies of scale. The high initial cost of designing and machining the mold is amortized over hundreds of thousands, or millions, of produced units, making the per-unit cost of each lunch box minimal. This perspective focuses on production efficiency by optimizing the mold for fast cycle times and minimal waste, often through multi-cavity designs that produce several boxes with each machine cycle. The mold is the fixed tool that transforms variable costs—plastic resin and machine time—into a standardized, profitable product. Its durability and maintenance schedule are closely monitored, as downtime for repair directly impacts production throughput and economic return.

Perspective Three: Material Science and Processing

This perspective views the mold as the crucible where raw plastic material is transformed. The mold's design is intrinsically linked to the properties of the chosen polymer, typically polypropylene (PP) or polyethylene (PE) for their balance of durability, flexibility, and food safety. The mold must account for the material's shrinkage rate as it cools; the cavity is machined slightly oversized so the final box dimensions are correct. The surface finish of the mold cavity is also critical—it is polished to a specific grade to give the plastic a smooth, easy-to-clean interior, or it may be textured to provide grip or a matte appearance. This perspective also involves managing the flow of molten plastic through runners and gates into the cavity, ensuring it fills evenly without defects like weld lines or air traps that could weaken the structure.

Perspective Four: End-User Interaction and Safety

The mold is the indirect designer of the user experience. It defines the lunch box's ergonomic and functional features. The mold forms the comfortable grip on the handle, the secure seal on the lid's rim, the stacking ribs on the bottom, and the compartments inside. From a safety and compliance standpoint, the mold must produce a product that meets food contact regulations. This means the mold itself must be made from appropriate steels and maintained to avoid contamination, and it must form the plastic into a shape with no sharp edges or inaccessible crevices where bacteria could grow. The durability of the hinge, the reliability of the latch, and the overall robustness of the box—all qualities tested by the user—are predetermined by the precision and quality of the mold's construction.

The lunch box mold is far more than a simple shape-maker. It is an engineered system for efficient production, an economic tool for scaling manufacturing, a processor of specialized materials, and the origin point of a product's functional and safe interaction with the consumer. Each perspective—engineering, economic, material, and user-centric—highlights a different set of requirements and considerations that converge in the design and operation of this essential manufacturing tool.

Contact Us

Email: [email protected]; Or fill out the contact form below.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français