Mold for Plastic Cups: Properties and Precautions

Molds for plastic cups are crucial tools in the manufacturing process of one of the commonly used products across various industries, including food and beverage, packaging, and medical sectors. A plastic cup mold is designed to create the shape of plastic cups, which are produced using different plastic materials such as polypropylene, polyethylene, and polystyrene. These molds are used in the injection molding process, where plastic is melted and injected into the mold to take the desired shape.

Key Properties of Molds for Plastic Cups

1. Precision and Accuracy

The important property of a mold for plastic cups is its ability to produce precise and accurate results. Molds are engineered with high tolerance levels to ensure that each plastic cup produced is uniform in shape and size. Any imperfections in the mold can defects such as thin spots, warping, or uneven walls, which can compromise the quality and functionality of the cups.

To achieve this level of precision, molds are crafted from high-quality materials such as steel, aluminum, or other alloys, which are capable of withstanding the pressures and temperatures involved in the injection molding process. The mold must also be designed to ensure that the plastic fills the cavity evenly and completely, without causing stress points or inconsistencies in the final product.

2. Material Durability

Molds for plastic cups are subjected to repeated use, high temperatures, and mechanical stress during the injection molding process. Therefore, they must be made from durable materials that can withstand these conditions without degrading over time. Steel is a common choice for mold construction due to its strength, durability, and ability to retain sharp details even after prolonged use.

Additionally, molds are often treated with surface coatings or finishes that help resist wear and tear. Some molds are also made from aluminum, which is lighter and more cost-effective but may not be as long-lasting as steel. The material of the mold directly impacts the mold's lifespan, production speed, and the overall quality of the plastic cups.

3. Ease of Maintenance

The ease of maintenance is another important property of plastic cup molds. To ensure consistent performance over time, it is crucial that molds can be easily cleaned, inspected, and repaired. Mold cavities can accumulate plastic residue, which, if not removed, can defects in subsequent production runs. Molds should be designed with easy access to critical areas for cleaning and maintenance.

Additionally, molds that are designed with modular components allow for easier replacement of individual parts such as cooling channels, ejector pins, and cavities. This flexibility ensures that the mold can be repaired or refurbished efficiently, extending its lifespan and reducing downtime.

4. Heat Management

Effective heat management is a critical property of molds for plastic cups. During the injection molding process, the plastic material is heated to a high temperature before being injected into the mold. Once the plastic is injected, it needs to cool quickly and evenly to maintain the desired shape and quality. A well-designed mold will have built-in cooling channels that allow for efficient heat dissipation.

Proper cooling helps prevent defects such as warping, deformation, and uneven thickness, which can occur if the plastic cools too slowly or unevenly. The design of the mold, including the placement and size of the cooling channels, is therefore an important factor in the efficiency and quality of the molding process.

5. Complexity of Design

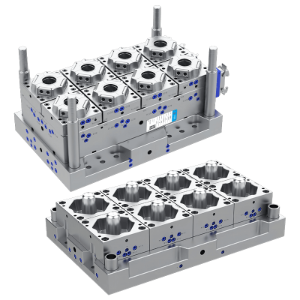

The design complexity of a plastic cup mold can vary depending on the type of cup being produced. Basic cups may require simpler molds, while more intricate designs, such as those with handles, embossed logos, or specialized shapes, may require more complex molds. Molds can be single cavity or multi-cavity, with multi-cavity molds allowing for the production of several cups at once, thereby increasing production efficiency.

The mold’s design will also affect the speed of the molding process. More complex designs may take longer to manufacture and may require longer cycle times during production. As a result, manufacturers must balance the desired cup features with the cost and time involved in mold production.

Precautions When Using Molds for Plastic Cups

1. Proper Mold Alignment and Installation

To ensure that the plastic cups produced are of the quality, it is essential to ensure that the mold is properly aligned and installed in the injection molding machine. Misalignment during the molding process can defects such as uneven walls, incomplete fills, or even mold damage. Operators should ensure that the mold is securely mounted and aligned with the injection molding machine to prevent these issues.

In addition, the machine should be calibrated to ensure that the injection pressure, temperature, and cycle time are set correctly. Improper settings can suboptimal mold performance and reduce the quality of the final product.

2. Temperature Control

Temperature control during the molding process is vital to prevent defects such as warping, cracking, or uneven wall thickness. The mold should be kept at the temperature range to allow the plastic to cool evenly. If the mold is too hot, the plastic may deform or become too soft, while if it is too cold, the plastic may solidify too quickly, preventing it from filling the mold completely.

Manufacturers should use temperature-controlled systems and monitoring equipment to maintain consistent mold temperatures. Temperature fluctuations can negatively affect the performance of the mold and the quality of the molded plastic cups.

Contact Us

Email: [email protected]; Or fill out the contact form below.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français