Introduction to Thin Wall Food Container Mold

From a production standpoint, the Thin Wall Food Container Mold is designed to operate under high injection speeds and short cycle times. This is important because the containers produced are intended for mass consumption in sectors such as catering, food delivery, and takeaway services. The mold's design enables manufacturers to produce large volumes of containers within a limited time frame, making it suitable for high-efficiency operations.

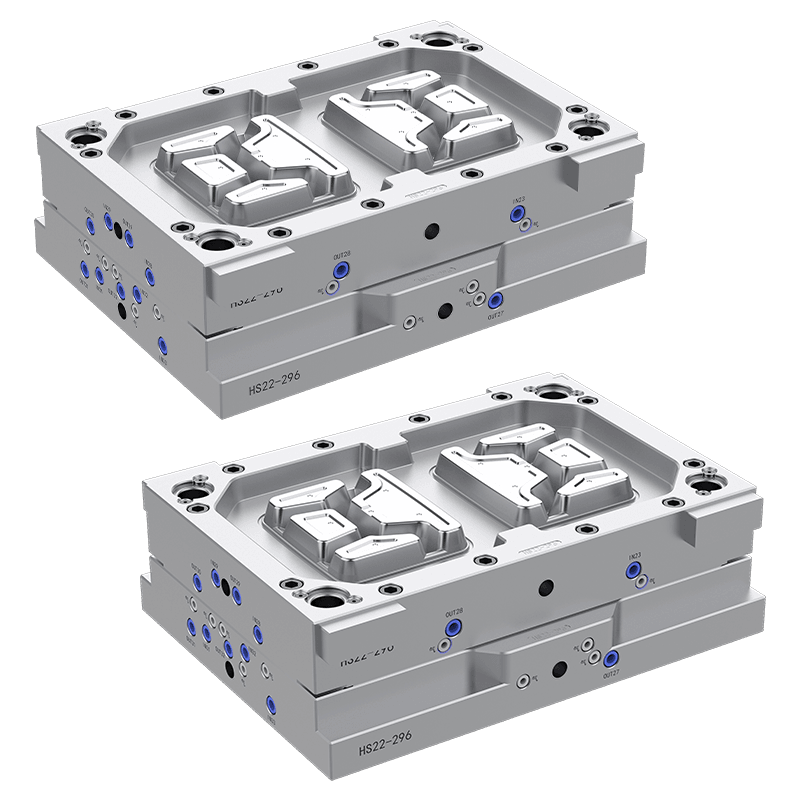

The structural design of the Thin Wall Food Container Mold is crucial for maintaining precision and consistency. Because the walls of the food containers are very thin—often less than one millimeter—there is little room for error during injection. The mold must ensure uniform wall thickness throughout the entire container, including corners and rims, to avoid weak points that could compromise the integrity of the finished product. This level of precision is made possible through detailed mold cavity engineering and optimized cooling channels.

In terms of materials, the Thin Wall Food Container Mold is typically constructed from hardened steel or other robust alloys that can withstand high injection pressures and temperatures. These materials also offer the necessary resistance to wear over long production runs. Since the molds are used repetitively in fast-paced settings, their durability directly affects the overall efficiency and maintenance schedule of the molding process.

The cooling system of the Thin Wall Food Container Mold is another critical aspect. Effective cooling reduces cycle time, which in turn increases output. Because thin-wall parts cool faster than thick-wall ones, the mold must be designed with advanced cooling channels that allow even temperature distribution. This ensures dimensional stability and helps prevent warping or shrinkage in the finished container.

Automation integration is a common feature when using the Thin Wall Food Container Mold. Many factories include robotic systems for part removal and stacking, which minimizes manual handling and reduces production time. This automation not only enhances productivity but also helps maintain cleanliness and consistency, both of which are important in food-grade container manufacturing.

Hygiene is a central consideration in the application of the Thin Wall Food Container Mold. Since the containers are used to store food, the molds must meet certain sanitary standards. This includes ensuring that the mold design allows for easy cleaning and that the materials used in construction are resistant to corrosion or chemical degradation from cleaning agents.

Customization options also play a role in the appeal of the Thin Wall Food Container Mold. Manufacturers may require different shapes, sizes, or branding features depending on market demands. The mold can be tailored to include logos, product codes, or stacking features that improve space utilization during transportation and storage. This adaptability gives companies greater flexibility in meeting customer needs.

In terms of environmental considerations, the Thin Wall Food Container Mold supports the production of containers that use less plastic than traditional models, contributing to material savings. The thinner walls result in reduced resource usage while maintaining adequate strength for safe food storage. This efficiency aligns with broader efforts in many industries to reduce waste and improve sustainability.

Technological advances have also contributed to improvements in the Thin Wall Food Container Mold. Modern simulation software allows for detailed analysis of material flow and mold behavior under various conditions, helping designers optimize the mold before it enters production. This reduces development costs and minimizes trial-and-error adjustments.

Contact Us

Email: [email protected]; Or fill out the contact form below.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français