Plastic Fork Mold: Selection Guide for Efficient Manufacturing

Plastic forks are ubiquitous in food service, offering a convenient, disposable alternative to metal cutlery. The production of plastic forks depends largely on the quality and design of the Plastic fork molds used in injection molding. Selecting the right plastic fork mold is crucial for achieving product consistency, reducing waste, and optimizing production efficiency.

The mold material determines its durability, resistance to wear, and suitability for different production volumes.

Tool Steel: Many plastic fork molds are made from hardened tool steel, such as P20 or H13 grades. These steels provide hardness and resistance to abrasion, making them suitable for high-volume production.

Stainless Steel: Used when corrosion resistance is important, especially if the mold is exposed to moisture or aggressive cleaning agents.

Aluminum: Less common but sometimes chosen for prototyping or short runs due to its lightweight and faster machining, though it wears faster than steel.

Selecting the appropriate mold material balances cost, durability, and production needs.

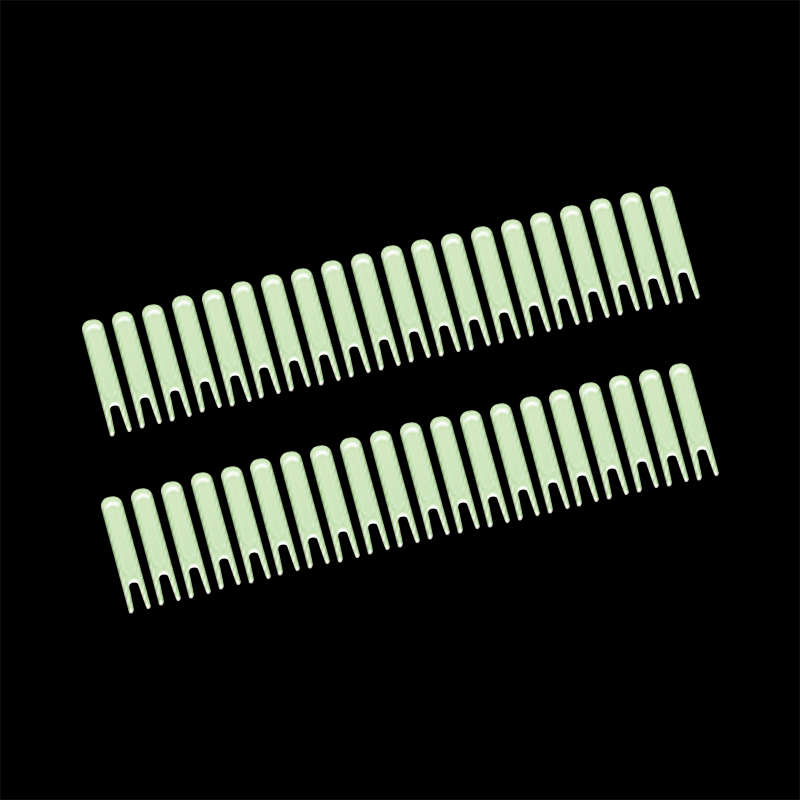

The number of cavities in the mold directly influences production efficiency.

Single-Cavity Molds: Produce one fork per injection cycle, suitable for small-scale production or product testing.

Multi-Cavity Molds: Can have multiple cavities (often 8, 16, or 32), producing several forks at once and dramatically increasing output. These molds are ideal for mass production.

The cavity layout should ensure uniform filling and ease of cooling, preventing defects like warping or incomplete molding.

Several design elements impact the quality and manufacturability of plastic forks.

Gate Type and Location: Common gate types include pin, edge, or submarine gates. The gate should allow smooth plastic flow without leaving visible marks on the fork's functional parts, such as the tines.

Cooling Channels: Efficient cooling reduces cycle time and helps maintain dimensional stability. Well-designed cooling systems ensure even temperature distribution, internal stresses.

Ejector System: Proper ejector pin placement prevents deformation during part removal and ensures smooth operation.

These features collectively influence production speed and fork quality.

Plastic forks are typically made from materials like polypropylene (PP), polystyrene (PS), or biodegradable plastics such as PLA.

The mold must be designed to accommodate the thermal and flow characteristics of the chosen plastic.

For biodegradable plastics, molds may require special venting or surface finishes to manage material-specific flow behavior.

Matching the mold design to the plastic material is critical for defect-free products.

Plastic forks require a smooth finish to ensure comfort and safety for users.

Mold cavities should be highly polished to reduce friction during ejection and improve surface gloss.

Tine edges and other detailed areas need precise machining to prevent rough spots or flash, which could affect user experience.

High-precision molds minimize post-processing and improve overall product quality.

Maintenance and Longevity Considerations

Plastic fork molds undergo repetitive high-pressure cycles, making durability and maintenance essential.

Wear Resistance: Hardened steels and surface treatments like nitriding can extend mold life.

Ease of Cleaning: Smooth surfaces and accessible design simplify cleaning, reducing downtime.

Repairability: Modular mold components facilitate quick repairs or cavity replacements.

Proper maintenance ensures consistent production and lowers long-term costs.

Mold cost depends on complexity, size, cavity number, and materials used.

Multi-cavity molds have higher upfront costs but lower per-piece costs due to increased output.

Simpler molds are less expensive but may not meet high-volume production demands.

Balancing mold cost with expected production volume and product quality requirements is essential.

A well-chosen mold represents a sound investment by optimizing manufacturing efficiency and product consistency.

Contact Us

Email: [email protected]; Or fill out the contact form below.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français