What Are the Material and Craftsmanship Considerations of Plastic Food Container Mold?

The consideration when discussing the Plastic Food Container Mold is the material used for the mold itself. Since the mold must withstand high pressure and temperatures during the injection molding process, the material selected must be both durable and resistant to wear. Many commonly, molds for plastic food containers are made from high-grade tool steels such as H13 or P20 steel. H13 steel is preferred for the mold cavities because it offers resistance to thermal fatigue, which is important given the repeated heating and cooling cycles molds undergo. P20 steel, while less heat resistant than H13, is often used for mold bases or less critical areas due to its good machinability and lower cost.

In addition to steel, surface treatments and coatings are frequently applied to the Plastic Food Container Mold to enhance performance. Techniques like nitriding or chrome plating increase the surface hardness of the mold cavities, reducing wear and extending the mold's operational lifespan. These treatments also help maintain the smoothness of the cavity surface, which directly affects the quality of the plastic containers produced, ensuring they have a flawless finish without defects such as scratches or marks.

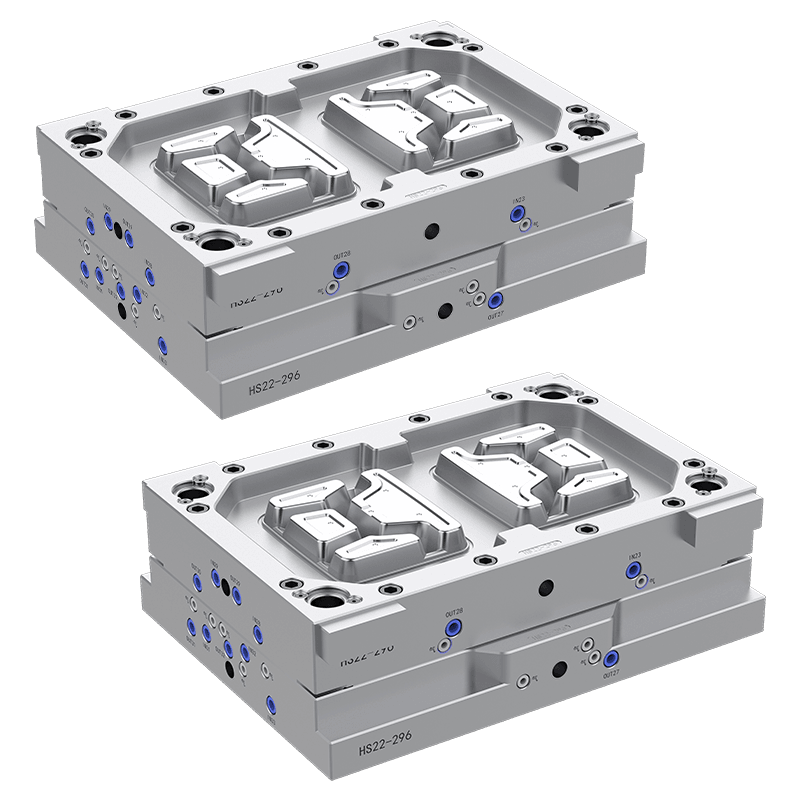

The craftsmanship involved in creating a Plastic Food Container Mold is as important as the materials used. Mold making requires high precision and skill to ensure that the dimensions and surface finish of the mold cavities are exact. The mold must be designed to create containers that meet strict specifications regarding size, wall thickness, and detail, such as locking lids or sealing features. These details affect the container's functionality, including its ability to securely store food and prevent leaks.

Machining the mold involves several steps. Computer numerical control (CNC) milling machines are commonly used to cut the steel into the precise shapes required for the mold cavities. Electrical discharge machining (EDM) may be employed to produce intricate details or sharp corners that are difficult to machine with conventional tools. After machining, the cavities undergo polishing to achieve a smooth finish, which helps produce containers with clear surfaces and prevents material from sticking inside the mold.

Cooling channel design is a critical aspect of craftsmanship in the Plastic Food Container Mold. These channels regulate the mold's temperature during injection molding, allowing the molten plastic to solidify evenly and quickly. Proper cooling reduces cycle time, increases production efficiency, and prevents defects such as warping or uneven thickness. Designing efficient cooling channels requires precise engineering to balance cooling speed with the structural integrity of the mold.

The mold design also incorporates venting systems to allow air to escape during the injection process. Without proper vents, trapped air can cause incomplete fills or surface blemishes on the containers. Crafting effective vents requires careful placement and sizing to ensure that they do not interfere with the final container shape or create weak spots.

Another key feature in the craftsmanship of a Plastic Food Container Mold is the ejection system. After the plastic solidifies, the container must be removed from the mold without damage. Ejector pins or plates are positioned strategically to push the container out smoothly. The ejection system must apply enough force to release the container but not so much as to cause deformation, especially in areas like thin walls or delicate locking mechanisms.

In recent years, technological advancements have improved both materials and craftsmanship in the manufacturing of Plastic Food Container Molds. For example, some manufacturers use high-speed machining techniques to reduce production times while maintaining precision. Others utilize simulation software to optimize mold design, predicting how molten plastic flows and cools inside the mold to avoid defects and improve overall product quality.

Contact Us

Email: [email protected]; Or fill out the contact form below.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français