Plastic Food Container Mould: Material Selection and Durability

Material Selection and Durability

One of the significant advantages of plastic food container moulds is the ability to use a variety of materials that offer high durability, lightweight properties, and food safety. The materials commonly used for plastic food containers include polypropylene (PP), polyethylene (PE), and polystyrene (PS). These plastics are selected for their resistance to cracking, breaking, and degradation over time.

Polypropylene is one of the popular choices for food containers because of its high melting point, which makes it suitable for both cold and hot food storage. It also has good resistance to moisture, chemicals, and oils, which is crucial for maintaining the quality and freshness of food. Polyethylene, on the other hand, is a more cost-effective option, often used for disposable containers such as takeout boxes or bags. Polystyrene is commonly used for single-use containers like cups and plates, as it provides good clarity and rigidity.

The durability of the materials used in plastic food container moulds ensures that the containers will not break or deform easily, even under pressure or when exposed to temperatures. This reliability is essential for food packaging, as it prevents spills, leaks, or contamination, ensuring the safety and integrity of the food inside.

Design Flexibility and Customization

Plastic food container moulds offer a high degree of design flexibility, allowing manufacturers to produce containers in a wide range of shapes, sizes, and features. The moulding process can create containers with varying thicknesses, designs, and even compartments, depending on the needs of the food industry.

The ability to design containers that are stackable, easy to store, and easy to transport is another significant advantage of plastic food container moulds. Many food containers are designed to be compact and space-efficient, especially for takeout or meal prep containers. The moulding process allows for features such as snap-on lids, tamper-evident seals, and vented covers, which help improve food safety and freshness.

Customization is also a key feature of plastic food container moulds. Manufacturers can tailor the mould to meet the specific requirements of their clients, whether it's for a particular type of food, branding, or functionality. For instance, some containers are designed to be microwave-safe, while others are suitable for freezing or storing liquids. The versatility of the moulding process makes it possible to create containers for a variety of food storage and serving needs, from single-portion servings to larger, family-sized containers.

Production Efficiency and Speed

Another important benefit of plastic food container moulds is their ability to facilitate high-volume production with consistent quality. The injection moulding process, commonly used for plastic food container production, allows manufacturers to produce large quantities of containers in a relatively short amount of time. This makes it possible to meet the growing demand for food containers in both the retail and food service industries.

The high-speed nature of injection moulding ensures that manufacturers can create large batches of food containers with high precision. The use of automated systems in the moulding process further improves production efficiency by human intervention, reducing the likelihood of defects, and speeding up the overall production cycle.

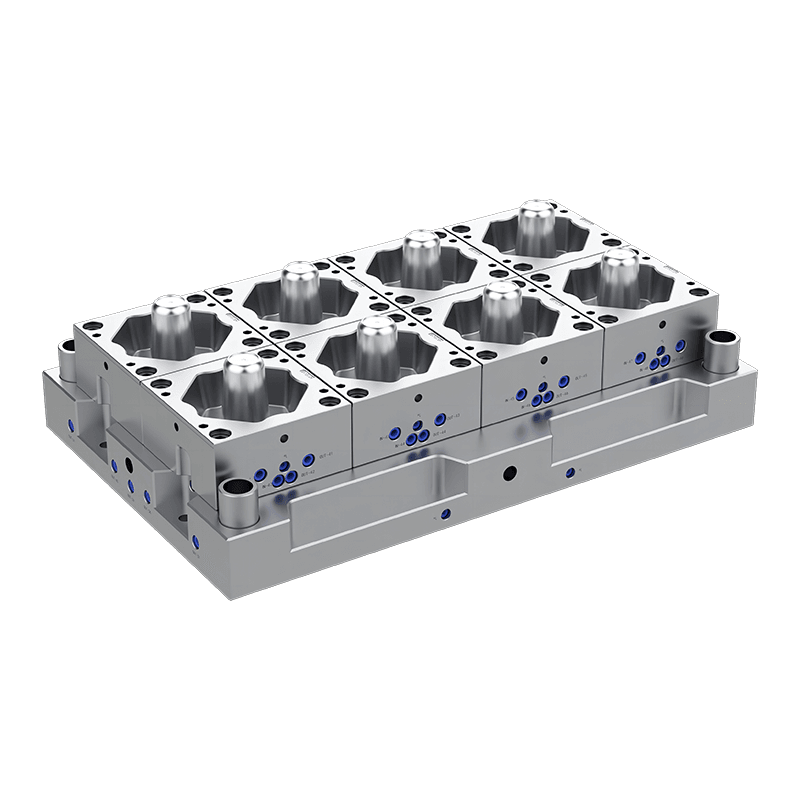

Plastic food container moulds can also be designed to accommodate multiple cavities, meaning that multiple containers can be produced in a single cycle. This significantly increases production output and reduces the cost per unit, making the manufacturing process more efficient. The efficiency of the moulding process is a key factor in meeting market demand while maintaining product quality and consistency.

Cost-Effectiveness and Environmental Considerations

Plastic food container moulds are not only efficient in terms of production speed but also cost-effective, making them an attractive option for manufacturers looking to minimize production costs. The moulding process itself is relatively inexpensive once the moulds are created, as the material costs for plastics like polypropylene and polyethylene are generally low compared to other materials like glass or metal.

The longevity and reusability of plastic food container moulds contribute to cost savings. Since moulds can be used repeatedly to produce large quantities of containers, the initial investment in the moulds can be spread across many production runs, lowering the overall per-unit cost.

From an environmental perspective, plastic food container moulds are also evolving to accommodate more sustainable practices. Many manufacturers are now focusing on using recycled plastic materials or designing containers that are recyclable after use. Some food container moulds are even being developed to produce biodegradable containers that break down over time, offering a more eco-friendly alternative to traditional plastic containers. This shift toward sustainability is helping to meet consumer demand for environmentally conscious packaging options while still maintaining the functionality and durability of the containers.

Contact Us

Email: [email protected]; Or fill out the contact form below.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français