What Should Be Paid Attention to During the Process of Thin Wall Injection Moulding?

Thin wall injection moulding is a popular and efficient method used in the production of lightweight, high-precision plastic components. It has become especially important in industries such as packaging, automotive, medical, and consumer goods, where the demand for lightweight yet durable plastic parts is ever-increasing. The key feature of thin wall injection moulding is the ability to produce parts with walls that are typically less than 1mm thick, while maintaining structural integrity and aesthetic quality.

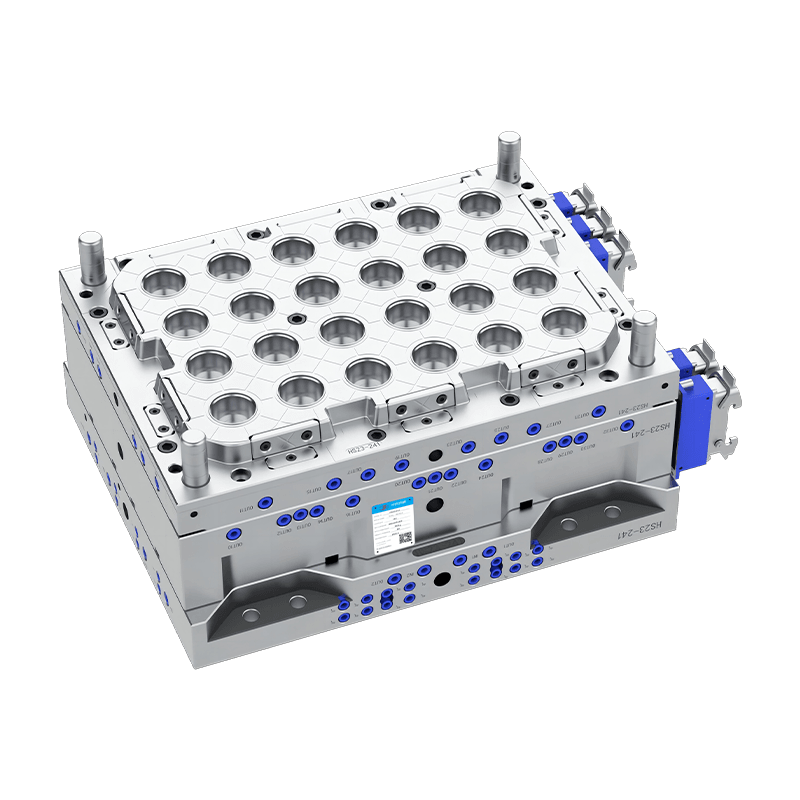

One of the crucial factors in thin wall injection moulding is the design of the mould itself. The success of the moulding process begins with a well-engineered mould that can withstand the high pressures and temperatures involved in producing thin-walled parts.

Gate Design: The gate is the point where the molten plastic enters the mould cavity. For thin wall parts, gate placement is essential to ensure that the material flows evenly throughout the cavity. Improper gate location can cause uneven filling, bring about defects like warping or incomplete parts. Hot runner systems are often used to ensure that the molten material remains at a consistent temperature during injection.

Parting Line and Venting: Parting lines, where two halves of the mould meet, must be designed carefully to avoid weak spots in the finished part. Additionally, effective venting is required to release air trapped in the cavity during injection. Poor venting can bring about short shots or voids, reducing the quality of the final part.

Cooling Channels: For thin wall injection moulding, precise cooling is necessary to prevent uneven cooling times, which can cause part warpage or sink marks. Moulds should be designed with efficient, evenly distributed cooling channels to ensure that the part cools uniformly and solidifies in a controlled manner.

The choice of material plays a critical role in thin wall injection moulding. Thin-walled components need to have high flowability to ensure that the molten plastic fills the mould cavity quickly and completely. Materials with low viscosity, such as certain types of polypropylene (PP), polystyrene (PS), or polyethylene (PE), are often preferred for their ability to flow into thin mould sections without leaving defects.

Viscosity: For thin wall applications, materials with low viscosity are better suited as they flow smoothly into the narrow cavities without clogging or experiencing premature solidification. High-viscosity materials can result in incomplete fill or slow cycle times, both of which bring about reduced production efficiency.

Thermal Stability: Since thin wall injection moulding operates at high temperatures, the selected material must have good thermal stability to resist degradation during processing. Materials with poor thermal properties may degrade, resulting in poor surface finish or reduced part strength.

Strength-to-Weight Ratio: Thin-walled parts need to be lightweight yet strong enough to perform their intended function. Materials that have a high strength-to-weight ratio, such as reinforced plastics, are ideal for such applications.

The injection pressure and speed are critical factors in the thin wall injection moulding process. Due to the small wall thickness of the parts, the material needs to be injected at a high pressure to ensure that it fills the mould completely and evenly before cooling begins.

Injection Speed: Thin walls require fast injection speeds to allow the molten plastic to flow into the cavity quickly before it solidifies. Slow injection speeds can result in incomplete fills, short shots, or excessive cooling time, which ultimately increases cycle times.

Injection Pressure: To achieve the desired part quality, the right injection pressure must be applied. Too low a pressure can cause underfilled cavities, while too high a pressure can bring about flash, warping, or damage to the mould. A careful balance of injection pressure is required to ensure that the plastic fills the mould accurately and without defects.

Contact Us

Email: [email protected]; Or fill out the contact form below.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français